anodize seal test|anodized aluminum test : dealers Seal Test. ASTM B 136 - Standard* method for measurement of stain resistance of anodic coatings on Aluminum. 1.1. Scope. 1.1 This method is intended to determine whether anodic . A TV 0800 Online está em conformidade com a Lei de Direitos Autorais do Milênio Digital (DMCA) e 17 USC 512. Em conformidade com a Lei de Direitos Autorais do Milênio Digital ("DMCA") e outras leis relevantes de propriedade intelectual, é nossa intenção responder a qualquer notificação de violação e tome as medidas cabíveis.

{plog:ftitle_list}

Resultado da The latest tweets from @icespicee_

To check whether the part is successfully sealed one of the most common tests for hot water sealed parts is the dye test which basically checks whether the pores have been fully hydrated and a full barrier has been produced. Another test is the salt spray test in accordance .ASTM B136 describes a dye stain test to use to check seal quality on a pass/fail . The most common of these test methods include film thickness measurement, the seal of anodic coatings, and conductivity measurement. Knowing the basics of each method and the influences that affect each .Seal Test. ASTM B 136 - Standard* method for measurement of stain resistance of anodic coatings on Aluminum. 1.1. Scope. 1.1 This method is intended to determine whether anodic .

ASTM B136 describes a dye stain test to use to check seal quality on a pass/fail basis. The test requires Nitric Acid (40%) for two minutes and blue dye for 5 minutes, if there is a color change the parts fail (check out the spec .

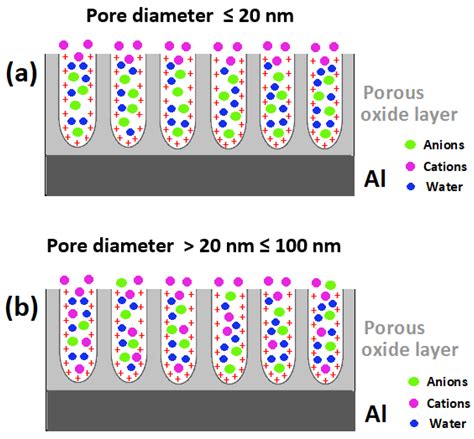

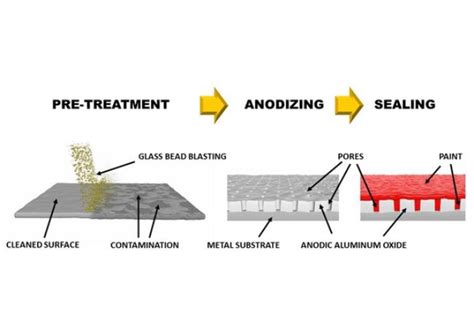

Standard Test Method for Seal Quality of Anodic Coatings on Aluminum by Acid Dissolution. Significance and Use. 3.1 This test method describes a destructive test procedure . The sealing step is an important step employed in the aluminum anodization process principally to preserve the aesthetics [1] and improve the corrosion resistance of the anodized aluminum by ensuring that the pores of . Answer: Your method may seem to work, but it is not the “official” quick test method for checking quality of seal on anodic coatings. The recognized test is the one contained in .

A destructive test for ascertaining seal quality (and coating weight if necessary) utilizes a solution of chromic and phosphoric acids at selected temperatures. Because it dissolves the .

Sealing quality tester for anodic coatings on aluminum. Measuring anodic film thickness with an ISOSCOPE® leaves the job only half done since the weather resistance of a finish is also a . The sealing step is an important step employed in the aluminum anodization process principally to preserve the aesthetics [1] and improve the corrosion resistance of the anodized aluminum by ensuring that the pores of . Sealing of anodized aluminum is considered to be the most important of all the various steps in the anodizing process, and Coventya’s Michael McGinty explains how you seal ultimately determines the performance of the anodic oxide in its end-use environment. Anodized Aluminum Coating Weight Testing ASTM B137. Q. We are adhering to anodising MIL-A-8625 / MIL-PRF-8625 [on DLA] . ASTM B136, the anodize stain resistance test, is a quick and easy seal test for either you or your anodizer (requires handling a bit of nitric acid safely). Not for alloys > 2% Cu or 4.5% Si, though.

Anodized aluminum is for the most part a robust, quality finish that is readily obtained through any number of chemical processing houses. ️ Learn here more about anodize finishes . Temperature, concentration, immersion time and purity are all necessary to be monitored and controlled. A simple “seal integrity test” per ASTM B136 can . A single-stage process has the disadvantage of requiring a minimum 24-hour cure period before seal quality testing (i.e. modified dye stain or acid dissolution test) can be performed. The duplex stage process involves a shorter cold seal time of five minutes for coatings less than 0.5 mils in thickness and eight minutes for coatings greater . The recognized test is the one contained in ASTM B136-84, “Modified Stain Test”. I quote a summary of the procedure from part of that document, “The method comprises contacting the test area of the anodized specimen with nitric acid solution and, after rinsing and drying, applying a special dye solution followed by rinsing and rubbing the . The authoritative public forum for Metal Finishing since 1989 -----Hot (boiling) DI water seal after anodizing. Current question and answers: Q. Anodizing is a finishing technique that I use to support my hobby in electronics. I use this process to finish front and rear panels, and I engrave the panels before anodizing to eliminate the high cost and lead time of one-off .

Anodized aluminum is very suitable for applications involving exposure to sea water and is routinely used for parts such as masts. Corrosion resistance is good; however, the parts should be kept clean. . B680-80 (2004) – Standard Test Method for Seal Quality of Anodic Coatings on Aluminum by Acid Dissolution; B117-07a – Standard Practice .

how to measure anodized aluminum

chromium anodized aluminum seal

Sealing anodized Aluminum. Q. Hi. We have some parts that we send out for anodizing per MIL-A-8625 / MIL-PRF-8625 [on DLA]. They are also required to be sealed. Exactly what does the sealing process do for the product? . Those who are more serious about seal testing perform a weight-loss test, per ASTM B680. A panel or part is soaked in a .

This paper is attributed to a new technology for anodize seal and hence a very brief information is included for seal tests. Dye Stain Tests This is a common test for checking seal application. At one time, this was accepted as only test needed to check if .

This light coat of anodized aluminum is a barrier against corrosion that, apart from adding to the object’s strength and durability, also preserves its appearance. . Alkaline clean, rinse, etch, rinse, deoxidize, rinse, anodize, rinse, dye, rinse, seal, rinse, hot water dip. Normally, there should be two rinse tanks between each process .

Seal the part using hot water (200ºF or 93ºC), which leads to the formation of hydrated aluminum oxide crystal responsible for sealing the pores. . Using a basic voltmeter, you can check the success of the anodizing process. Clean the anodized part and test the part. A significant deviation in the conductivity of the part shows a problem .

Typical tests for anodized coatings include coating weight, seal quality, corrosion resistance, light fastness, and paint adhesion. Hardcoatings are additionally often tested for thickness and abrasion resistance. Again Mil-A-8625 is a good starting point toward developing test requirements. Rework of Anodized Coatings“CHEMEON eTCP represents the evolution of trivalent chromium pretreatments by replacing the known carcinogen hexavalent chrome and its identifiable yellow/gold hue with the violet to blue hues of CHEMEON eTCP. We developed the CHEMEON eTCP technology as a safe, non-carcinogenic trivalent chromium conversion coating and anodic seal to meet the needs of .Test Methods For Type II Anodized Aluminum. Oxide Coating Thickness. ASTM B 244-97 (2002) ASTM B 487-85 (2007) Min Thickness. Class I. 18 Microns (µ) Class II. . Where extreme abrasion resistance is required do not seal as some softening is encountered. Type III Anodize Thickness Guide. Alloy. Major Constituent(in) Maximum Thickness* Color . Hard Coat anodizing provides high wear resistance, typically scoring a weight loss of 1.0-1.5 mg/1000 cycles in the ASTM D4060 abrasion resistance test. Regular anodizing offers moderate wear resistance, scoring .

These categories are: anodize, seal, anti-mist, polyballs, make-up water, rinse, contamination, power capability, racks, cathodes, agitation, dry, appearance, quality control, and paint. . Aerospace anodizing involves . When you send the parts out for finishing, do not specify chromic acid anodizing or a chromic acid seal, and do specify "RoHS compliant". Best of luck! Regards, Ted Mooney, P.E. Striving to live Aloha finishing.com - Pine Beach, New Jersey January 2, 2011.

After anodizing, you have to seal the microscopic pores on the surface of the part to prevent further corrosion and improve performance. Without sealing the pores, anodized parts may feel sticky to the touch. . To assess the quality of anodization, you should test how resistant the part is to abrasion and corrosion. If the material finish .Type I - Chromic acid anodizing, conventional coatings produced from chromic acid bath (see 3.4.1) . Test specimens shall show no more than a total of 15 isolated pits (see 6.19), none larger than 0.031 inch in diameter, in a total of 150 square inches of test area grouped from five or more test pieces. . The hot deionized water seal is .Anodize film thickness Anodize film uniformity Anodize film density Abrasion resistance Corrosion resistance Fade resistance Reflectivity Image clarity Insulative properties Adhesion Sealing: Applicable Tests G.M.C. Cass Test Ford fact test Salt spray Weatherometer Fadometer U.V. Con Acid dissolution (ASTM B136-63T) Weight test Microscopic test

Type III - Hardcoat Anodizing: This process makes use of sulfuric acid as the electrolyte but is used to produce much thicker coatings than Type II MIL-A-8625/MIL-PRF-8625 anodizing — typically 12.7 to 50.8 μ (0.0005 to 0.002 in) due to a higher voltage, longer bath immersion time and lower bath temperature. This coating is harder than tool steel and is used . The purpose of the salt spray test is to validate the “health” of an anodize process line. W. John Fullen This test requires two weeks, which makes effective corrective action decisions paramount to avoiding long periods of downtime. By assimilation of many decades of Boeing documentation, external literature and consultation, an Anodize Troubleshooting .Test cell ø 6 mm(1): 14 - 1400 µS Test cell ø 13 mm: 3 - 200 µS Test cell ø 26 mm(1): 0,75 - 75 µS Note: Referenced to the standard measurement cell area of 133 mm2. Power supply: battery 9V6LR61 Dimensions (LxWxH): 160x80x30 mm Mass: 230 g (1) The meas. cells with a Ø of 6 mm or a Ø of 26 mm do not permit standardized

The R.O. will remove chloride. A turbidity test of the water with silver nitrate . Most references recommend using DI water in a minimum of the anodizing tank and the seal tank. Most places will use it in as many tanks as they can afford. To me, controlling it is a waste of lab time and "another tic to chase" as some of my British pilot .Re: Anodize (Type II Class I) Peeling off after Tape Test ive seen it in 7*** series alloys. i put it down to a bad batch of alloy . poorly mixed or burnished during machining. the alloying component is zinc which can corrode if patchy beneath the ano layer. but this is all speculation , but fits with the problems i once had. parts were re-made with different stock and problem went

It will require extra pieces of customer metal for destructive testing. Test results may add 3 or 4 weeks to obtain certifications. . Alloys 2024 and many aircraft alloys require a dichromate seal to meet the performance specifications of MIL 8625 Type 2, Class 1. . Anodized Aluminum Spacer Bars; Aluminum Sheet for Lighting Products;

Additionally, longer anodize immersion times may be counterproductive to paint adhesion characteristics17. The following Anodize rinse should be relatively short to avoid potential lower hydration values4 for parts that are subsequently Sealed. Seal immersion time is specified (23-28 minutes) but being at the highest end of the allowed

anodized aluminum test

anodized aluminum sealant

WEB